If you're working in your garage this weekend, you might want to know what carbon brushes are. Continue reading!

Photos by: Adobe Stock Images

Photos by: Adobe Stock Images

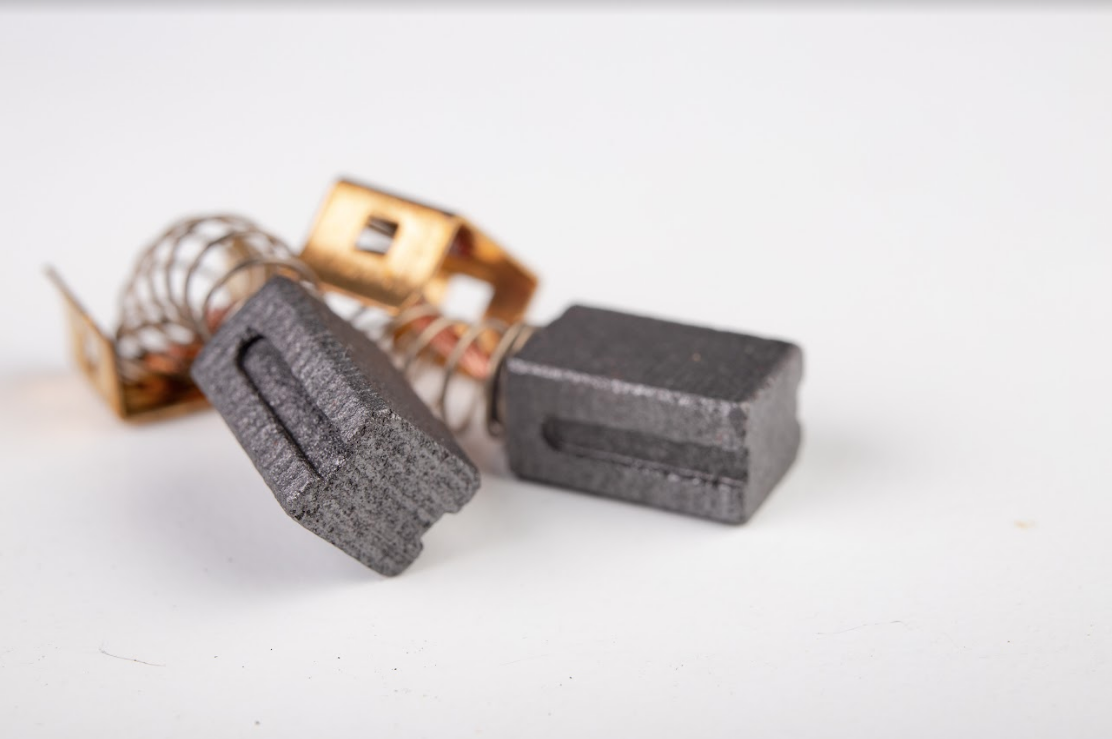

Carbon brushes, commonly referred to as sliding contacts, are electromechanical components that generate electrical currents from stationary wires to rotating areas of alternators and generators. Likewise, these brushes help move electricity from outside the motor to its central part, known as the motor's rotation area.

Originally, carbon brushes were made from wire that looked like standard wire brushes. However, it has been found that the wire brushes tend to wear out the commutator quickly, thus adding to some problems. At present, carbon brushes are soft and they tend to wear out due to frictional loads. This wear design is excellent because it makes them easily replaceable. In addition, carbon brushes play the role of minimizing damage to the motor. The carbon block, known as a brush, provides power back and forth from the stationary parts of a motor to the kinetic parts. Because of their practicality, these tools are used in a variety of ways. Curious Enough? Here are the uses of carbon brushes:

1. Industrial use

Carbon brushes are used on rotary electric commutator switches in high power resources such as electric generators and electric motors. These also facilitate the processing of device motors in windmills, cement works and hydropower plants. Because of their crucial role in construction truck engines, industrial carbon brushes are used to power battery-powered cars, cable cars and trolleybuses. Brushes connect the generator to the rotor via the commutator. As the brushes are worn out, rotating and static parts are protected from damage. For this reason, industrial brushes are specially designed for extreme temperatures. Also, check the carbon brush numbers before buying. Usually these are embossed on the front of the carbon. Checking this quality is important as this way you know the makeup of the brush.

2. Household use

Micro-carbon brushes are often used in battery-operated mini motors. This is done in order to transmit the power noiselessly and with the least amount of friction to kinetic parts such as wheels, razors and even into audio equipment. Did you also know that your household appliances are operated with carbon brushes? These tools are typical parts in household appliances. However, the carbon brushes used in these are smaller compared to their counterparts in the automotive and industrial industries. Power tools such as vacuum cleaner turbines, hair and hand dryers, and washing machines are common uses for this type of carbon brush. That being said, some of the common tools you might need to maintain your garden come with carbon brushes.

3. Use in motor vehicles

Cars with DC motors run universally. These vehicles use small and additional carbon brushes for DC motors, starters and alternators. Alternators are rotors with wire loops that create a magnetic field when electricity flows through them. Consequently, this transfers mechanical energy to electrical energy. In addition, carbon brushes are used in diesel and oil vehicles. This is a requirement for airbags to function during impact. The brushes are maximized by steering wheels when the car is in motion.

Take that away

Due to their wide range of uses, carbon brushes are of crucial importance for the smooth functioning of machines and devices. The brushes generate electrical currents for alternators and generators of various resources. With that in mind, it's important to do frequent engine cleaning to ensure air filters provide clean air to the engine. This also prevents commutator wear and copper dust from building up and damaging your brushes.