If you are looking for an activity that takes your time, you will be thrilled with immersing yourself in the CNC milling activity. It is also suitable for people who are interested in art, product development and production work. CNC is an abbreviation for Computer Numerical Control, and its milling cutter is used to cut various materials.

What is a CNC wood router?

A CNC wood router is an object that uses the Cartesian coordinate system as a control system to move in 3D and thus make everything from wood. The coordinates are entered into the controller, which is removed from the CAD program. The CAD program is used to create the design of the patterns, while the CAM program is used to translate the three coordinates. A wood router spins from 12500 rpm to 24000 rpm and uses both CAM and CAD applications, including AlphaCam and Bobcad.

Ten tips for using CNC wood milling cutters

- Contrary to popular belief, it is better to use retaining screws rather than holding tabs because many people find it difficult to find a balance between using sufficient retaining screws. However, make sure to drill holes in the corruption plate that will support the material you made.

- Make sure that the CNC is well calibrated or not square to ensure that the input and output match.

- Make sure the correct shape of the chisel is used as this affects both the feed rate and the edge of the product. Compression drills are also great as they make the surface smooth on all sides.

- Use the appropriate grinder. After checking the calibration, it is important to use the correct end mill as there are many different types of end mills.

- To be able to cut parts with clean edges accurately, it is important to perform various roughing and finishing operations, especially during the CAM phase. The first pass ensures that there is a wide cut, while the last stage ensures that the edges are clean.

- Use the feed and adjust it according to the corresponding passage. The wrong feed rate can lead to a broken mill. The best feed rate for plywood is 80 inches per minute, while the depth is usually 0.4 inches.

- The depth of cut should be deeper than the actual thickness of the product material. This ensures a full depth cut.

- You need to use the lossless design carefully by placing each component as close as possible. This way you can save time and money because the end mill only cuts once.

- Limit the number of shafts as a small number of shafts ensures that large chips can escape and that there is enough space between the cutting edges.

- If you want to increase the speed, it is advisable to use knives with small diameters, which are preferably lowered by a quarter of their actual diameter.

frequently asked Questions

What can I do with the CNC router?

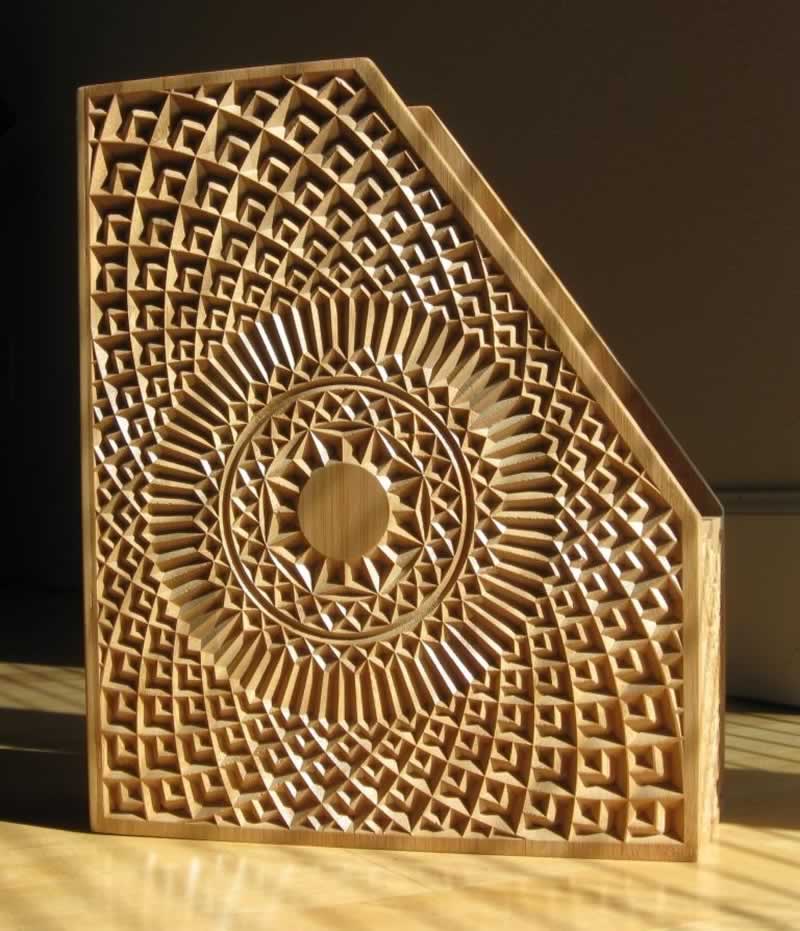

With a CNC router, musical instruments, signs, door carvings, furniture and decorations are made by cutting hard material such as wood, plastic and glass.

How does a CNC router work?

Different programming languages are used, but the common one is the G code, and this language controls the CNC machine. Route tool paths are created using the numerical control system. Therefore, the product is made with minimal waste and reduced time.

Can you CNC CNC wood?

Yes, you can use CNC wood and it is the most common material because it is light and therefore accessible to CNC.

How long does a CNC router last?

Without considering various factors that would affect the time to complete a product, the known time to complete 200 parts is typically 18 hours.

What does a CNC router cost?

The price range depends on the model and its characteristics. A hobby CNC price range is between $ 600 and $ 4,000. Low-end models are typically between $ 4,000 and $ 250,000, while the price range for high-end models is between $ 60,000 and $ 100,000.

Conclusion

CNC cutters are great machines for making products that require high precision. They are also excellent at reproducing patterns accurately and quickly.