USA / INTERNATIONAL

Lavatec has developed an innovative and patented solution that enables both to reduce CO2 emissions and industrial laundries to look for newer and better ways to satisfy customers and save energy costs. The new LAVACascade drying system is a real efficiency model that achieves energy savings of at least 50%, according to the company.

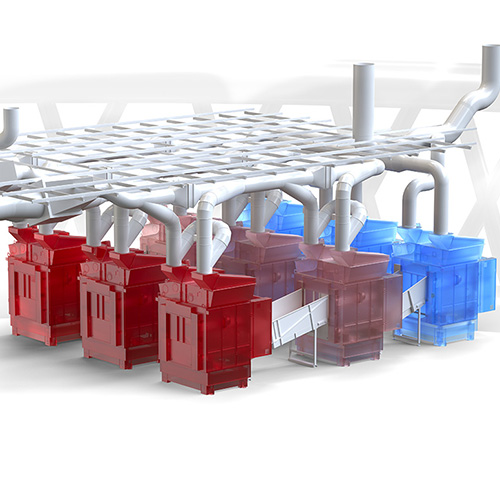

LAVACascade is a quick and easy three-step marvel that also pays off in terms of time and labor savings, says Lavatec. In the first phase, the laundry load is supplied with high heat. A middle stage recovers waste heat to maintain a constant temperature, followed by a final cooling stage. Each phase only takes a few minutes.

“This is a major advancement in the drying industry that has been in the making for several years. We used the same engineering approach that we use for our bespoke tunnel washers to design LAVACascade, ”stated Mark Thrasher, President and Co-Owner of Lavatec Laundry Technology.

“The end result is that we have developed an incredibly efficient system with a shorter drying time that can cut energy consumption by up to 75%. Last month we completed the installation of the first machine at a customer in Germany. The first results are excellent. "

Global call to action

Lavatec's Cascade technology is in line with the latest global developments to combat climate change and reduce CO2 emissions. The California Energy Commission approved standards for commercial and industrial laundries in December 2019. Short- and long-term goals for one to five years affect energy savings, emissions reductions and electricity consumption.

The LAVACascade system addresses and supports research results from the Nuremberg Institute for Technology, one of the largest universities of applied sciences in Germany, in many ways. Citing a 2010 federal statistical study that analyzed the total energy consumption of 3,800 laundry and cleaning companies, it was reported that 90% of total energy consumption was used to heat water. Although every company examined had systems for recovering or reusing water, only one company had installed a system for reusing waste heat from tumble dryers – and of the 28 dryers there were only four.

"In Europe and around the world, reducing carbon emissions is on the agenda of almost every government," admitted Thrasher. "As our customers want to reduce costs and meet new legal requirements, reducing energy and emissions has the full attention of commercial laundry operators."

The management of Lavatec believes that LAVACascade can improve almost any type of commercial laundry operation and is the perfect addition for people with a large amount of completely dry laundry. This includes, but is not limited to, the hospitality, healthcare, and uniform cleaning wash towels, and the mats and mops used to clean the floors in these facilities.

"These types of laundry operations have a very high amount of similar items that require a long drying time," said Thrasher. "In such situations, the potential for energy savings is enormous."

The first LAVACascade customer fits this profile. Coburger Handtuch is a regional service provider in Rödental that specializes in handling towels, cleaning mops and dirt protection mats. Company owner Joachim Krause is both a supporter and a promoter of environmentally friendly technologies and devices.

"As with every first start, we had some interesting situations during the installation that we learned from," summarized Thrasher. “It was mostly related to the placement of the machines and allowing proper airflow. The key is that the owner now understands that drying time and energy consumption are lower than originally calculated and expected. We are in discussion with several operators in North America and hope to announce more new orders soon. "