The table grinder consists of a motor shaft with two grinding wheels attached to the ends. A table grinder is defined as a type of grinder that is mounted on a workbench. This tool is used to grind various cutting tools by hand. One of the essential components in the structure and operation of a table grinder is the wheel.

This article explains the method of changing the wheels of a bench grinder.

Steps to change the wheels of a table grinder

Before you begin, you must take the necessary precautions. Wearing safety glasses is a safety measure. Another important factor to check is that the torque used to tighten the bolts to insert the wheel is not above the recommended value. This should be ensured as otherwise there is a high probability that the disc will come loose while the tool is in operation. Before you start the procedure, you also need to make sure that the new wheels used for the replacement are the correct speed and size of your grinder.

Some tools are required to replace the wheels easily and efficiently. The required tools are listed below. Make sure you have all of these in your immediate area before starting the process.

- screwdriver

- Safety gloves

- safety goggles

- Adjustable wrench

- Spare wheel

- Lubricating oil

Step 1: Security has to be the main concern

When handling strength equipment, protecting yourself and your environment should be a priority. For this purpose, the prescribed safety precautions must be observed in order to avoid possible dangers. Check that the grinder is not connected to the primary power source. If the device is connected to an emergency power source, the operator must ensure that it is also disconnected or unplugged. Pay attention to possible dangers that can be caused by the connection to the power source. If any are found, they must be removed easily.

Step 2: familiarize yourself with your tool

Getting to know how your table grinder works is essential. Even if you are sure to use the machine, you should give a short trial version. This act is believed to make the task easier. Therefore, before proceeding with the main procedure, it is recommended that you quickly check the bench grinder and try to analyze how it works. This trial version gives you an idea of which parts need to be replaced. Also scan the user guide that comes with the device when you buy it. This will tell you about the safe means to separate and replace the wheels of the table grinder.

Step 3: remove possible obstacles

Most table grinders have a guard that can be separated. This enables the wheel to be removed quickly and easily.

Step 4: take off your old wheels

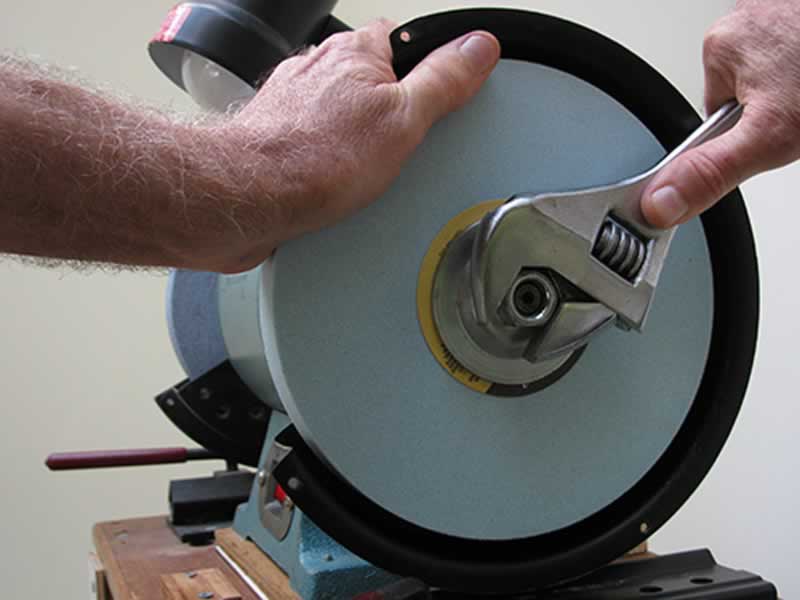

Examine the bench grinder and find out the location of the drive shaft. After determination, loosen the washer and the nut that holds the washer with a suitable wrench. Keep these things safe so you don't lose them. If you feel stiffness, lubricating oil must be applied to the nut-shaft joint. Make sure your hands are safe by protecting them with protective gloves, and then remove the wheel.

Step 5: attach the new wheels

You must have carefully observed how the old wheels were positioned before removing them. Get the new wheels and place them in a similar way. The type of connection varies depending on the type of disc used for assembly. Therefore you have to write down the positioning earlier. Insert the new wheels equally and move them to the largest possible point. Once this is done, tighten the newly placed wheels with the nut and washer.

The nut is reattached using a wrench. It should be noted here that you do not have to do the full amount when tightening the screws. You can leave a tolerance as soon as the wheels are in motion. They are tightened naturally by themselves.

Step 6: examine the machine

Once the above step is complete, you have removed the old wheels and replaced them with new ones. To ensure that it is successful, you should do a quick test check. Connect the machine and watch closely how the wheels turn. Watch and pay attention to unusual movements or noises. If you discover something atypical, such as For example, a noise or wobble, quickly disconnect the device from the power source by pulling the power plug. Then just go ahead and fix the problem. If necessary, try to loosen the wheels and make the necessary changes. Once set, go back to trail running. If everything looks good and good, switch off the machine and pull out the mains plug.

Final note

If you ever own a workshop, a bench grinder is one of the inevitable tools you need to have. The equipment is used to perform a variety of tasks. Some of them repair the broken blades, sharpen the blunt tools, and polish and repair small steel parts.

However, the table grinder also requires timely replacement of its parts, similar to all other machines. One of the main components that have to be replaced at regular intervals are the wheels of the table grinder. This replacement is necessary to ensure that most tools can be reached and the device can be operated efficiently.

Replacing the wheels is an easy task that you can do. However, if you're not sure enough, you can hire someone to do it for you. If you follow the steps to change a table grinder's wheels in the paragraphs above, you may get insight and security when you do things yourself. The only thing that should be strictly enforced is the security measures to be followed.